How To Choose A Temperature Controller?

Uncover the key considerations when choosing the ideal temperature controller to meet the unique requirements of your process and maximize both performance and efficiency.

1. Selecting the ideal temperature controller is essential to optimizing process efficiency, product quality and safety. This comprehensive guide outlines key considerations when making this important choice - helping ensure an informed choice that addresses all aspects of your process needs.

2. Understanding Temperature Controllers

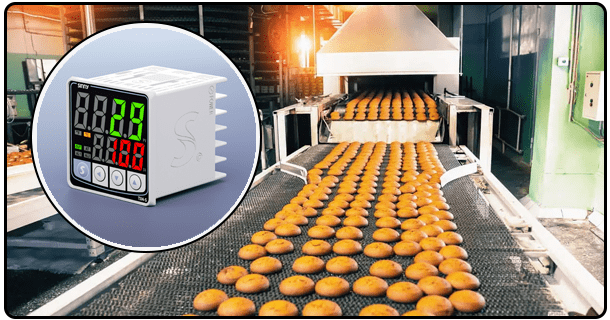

Temperature controllers play a vital role in maintaining ideal conditions for manufacturing processes or operations requiring exact control over environmental temperatures. Widely employed across industries like food production and climate regulation, temperature controllers play an integral part in keeping everything at an acceptable level for optimal operation and can ensure consistent production runs without disruptions from fluctuation within the specified ranges. Their primary function is maintaining this range to create ideal working environments, ensuring efficient processes are in place to operate at their full potential.

3. Assess Your Temperature Range Requirements

The first step in selecting an effective temperature controller for your application is identifying its required temperature range, which covers both low-end and high-end temperatures that your process might encounter. A controller that operates effectively within this temperature spectrum will guarantee precise control.

4. Selecting the Control Action

Temperature controllers provide various kinds of controls: some provide automatic temperature adjustments, while others use variable dials or buttons for manual changes. To select an action from these multiple choices, keep these points in mind when choosing your thermostat:

On/Off Control:

Ideal for applications where precise temperature regulation isn't of paramount importance.

Proportional Control:

Ideal for processes requiring greater temperature regulation to avoid temperature overshoot.

PID Control:

Ideal for applications requiring the highest levels of precision and responsiveness.

Select a control action that best matches the dynamics and sensitivity of your process in order to maintain stability.

5. Consider Your Power Supply

Temperature controllers can be powered either with AC or DC sources, depending on what's available at your facility. Be sure that whatever controller you purchase works well with your electrical system to avoid additional expenses associated with power conversion costs.

Sensor Type for Temperature Controllers

Temperature controllers use two primary sensor types for their temperature controls:

* Thermocouples:

These thermometers excel when measuring temperatures above 160F (67C). Their wide operating temperature range and fast response make them the go-to solution in such applications.

* Resistance Temperature Detectors (RTDs):

Resistance temperature detectors provide superior accuracy and stability at lower temperature ranges.

Consider both temperature range and accuracy requirements when choosing the sensor type to meet them in your process.

6. Output Requirements

Temperature controller output requirements can differ.

* Solid State Relays (SSRs) :

provide fast switching with high-frequency applications in mind.

* Analog Output:

Provides variable control when used with proportional valves or variable speed drives.

* Electromechanical Relay:

Perfect for lower frequency switching applications that involve simple on/off control.

Choose an output type that corresponds with the control action and devices being employed in your process.

7. Evaluate Environmental Factors

It is essential that controllers can withstand moisture, contaminants and temperature extremes without degrading performance in their operating environment. Therefore, evaluate its environmental factors when selecting controllers.

Modern temperature controllers boast many additional features and functions:

* Alarm Settings:

These alarm settings serve to inform operators about temperature deviations that could threaten operations.

* Limit Settings:

In order to prevent processes from exceeding safe temperature limits.

* User Interface:

This is for simple programming and monitoring.

Consider what features will enhance the operation and safety of your process.

8. Compliance and Standards

Make sure the temperature controller you purchase conforms with industry requirements and safety standards, especially those relevant to highly regulated industries like your own. Compliance can have legal as well as operational repercussions - so do take the time to verify this when choosing one!

Budget and Cost Considerations

The temperature controller you purchase must fulfill both features and reliability needs in your application without going for lower-priced options at the expense of long-term reliability and features that could prove more valuable in the future. Although lower-cost solutions might tempt you more readily, remember the benefits that may accrue by investing in something with greater features over time.