Industrial Temperature Controllers: Key Features and Applications

Explore the key features and applications of industrial temperature controllers. Learn how they improve product quality, enhance energy efficiency, and ensure safety in various industries.

1. Introduction

In industrial settings, maintaining precise temperature control is crucial for ensuring product quality and process efficiency. Industrial temperature controllers are essential devices that help achieve this by regulating the temperature within specified limits. This article explores the key features and applications of industrial temperature controllers, highlighting their importance in various industries.

Key Features of Industrial Temperature Controllers

Precision and Accuracy: Industrial temperature controllers are designed to provide precise and accurate temperature control. This precision is vital for maintaining consistent product quality and ensuring that processes are carried out under optimal conditions. Accurate temperature control helps prevent defects and ensures that products meet stringent quality standards.

Types of Controllers: There are several types of industrial temperature controllers, each offering different levels of control and precision. On/Off controllers are the simplest type, switching the heating or cooling device on or off when the temperature crosses a set point. Proportional controllers provide more precise control by adjusting the output proportionally to the difference between the set point and the actual temperature. PID (Proportional-Integral-Derivative) controllers offer the most accurate control by combining proportional, integral, and derivative actions to correct errors and maintain the desired temperature with minimal fluctuation.

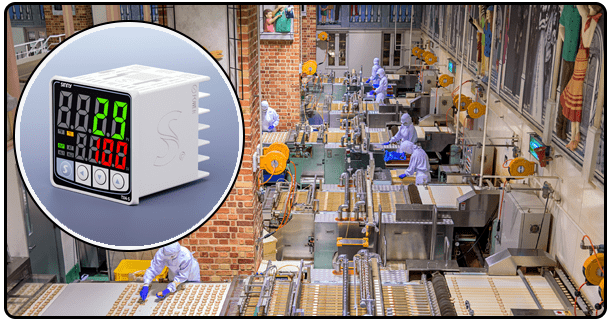

User Interface and Connectivity: Modern industrial temperature controllers often feature digital displays and user-friendly interfaces, making it easy for operators to monitor and adjust settings. Many controllers also offer remote monitoring and control capabilities, allowing operators to manage temperature settings from a distance. Integration with IoT (Internet of Things) enables advanced data analysis and predictive maintenance, further enhancing the efficiency and reliability of temperature control systems.

Durability and Reliability: Industrial temperature controllers are built to withstand harsh environments and demanding conditions. They are designed to be durable and reliable, ensuring consistent performance even in extreme temperatures, high humidity, and corrosive environments. This robustness is essential for maintaining continuous operation and minimizing downtime in industrial processes.

2. Applications in Various Industries

Pharmaceuticals: In the pharmaceutical industry, temperature control is vital to ensure the stability and efficacy of drugs. Industrial temperature controllers help maintain the required conditions during manufacturing and storage, preventing degradation and ensuring that medications meet safety and quality standards.

Food and Beverage: Temperature control is essential in food processing to ensure the safety and quality of food products. Industrial temperature controllers help maintain the correct temperatures during cooking, cooling, and storage processes, preventing spoilage and ensuring that food products are safe for consumption.

Chemical Manufacturing: In chemical manufacturing, precise temperature control is necessary to ensure consistent reactions and product quality. Industrial temperature controllers help maintain the optimal conditions for various chemical processes, preventing unwanted variations and ensuring that products meet specifications.

HVAC Systems: Heating, Ventilation, and Air Conditioning (HVAC) systems use temperature controllers to regulate indoor climates for comfort and efficiency. These controllers help maintain the desired temperature in residential, commercial, and industrial buildings, ensuring a comfortable environment and optimizing energy use.

Benefits of Using Industrial Temperature Controllers

Improved Product Quality: Consistent temperature control leads to higher quality products by ensuring that processes are carried out under optimal conditions. This consistency helps prevent defects and ensures that products meet stringent quality standards.

Energy Efficiency: Optimizing temperature control reduces energy consumption, leading to cost savings and a smaller environmental footprint. Efficient temperature control systems help minimize energy waste and lower operational costs.

Safety: Industrial temperature controllers prevent overheating and other temperature-related hazards, ensuring safe operation of equipment and processes. By maintaining precise temperature control, these devices help prevent accidents and ensure a safe working environment.

Cost Savings: By reducing waste and increasing operational efficiency, temperature controllers help lower production costs and improve profitability. Efficient temperature control systems minimize downtime and maintenance costs, contributing to overall cost savings.

Future Trends in Temperature Control Technology

Advancements in Digital Controllers: The integration of digital controllers with IoT (Internet of Things) and smart systems is enhancing the capabilities of temperature control technology. These advancements enable real-time monitoring, data analysis, and predictive maintenance, improving the efficiency and reliability of temperature control systems.

Miniaturization: Smaller, more efficient temperature controllers are being developed to meet the needs of modern industrial applications. These compact devices offer the same level of precision and control as larger systems, making them ideal for use in space-constrained environments.

Sustainability: There is a growing focus on developing eco-friendly and energy-efficient temperature control solutions to reduce environmental impact. Sustainable temperature control systems help minimize energy consumption and lower greenhouse gas emissions, contributing to a greener future.

3. Conclusion

In conclusion, industrial temperature controllers are essential for maintaining precise temperature control in various industries. They help improve product quality, enhance energy efficiency, ensure safety, and reduce costs. As technology advances, temperature controllers are becoming more sophisticated, offering even greater benefits to industrial processes.

FAQ

1. What are the key features of industrial temperature controllers?

Industrial temperature controllers offer precision, various control types (On/Off, Proportional, PID), user-friendly interfaces, and robust durability for harsh environments.

2. How do industrial temperature controllers improve product quality?

By maintaining precise temperature control, these controllers ensure consistent production conditions, leading to higher quality products.

3. What industries benefit from using industrial temperature controllers?

Industries such as pharmaceuticals, food and beverage, chemical manufacturing, and HVAC systems benefit from using temperature controllers to maintain optimal conditions.

4. What are the future trends in temperature control technology?

Future trends include advancements in digital controllers, integration with IoT, miniaturization, and the development of sustainable, energy-efficient solutions.

- Learn the Basics of Selecting an Appropriate Temperature Controller For Your Application

- How to Install and Calibrate an Industrial Temperature Controller: A Step-by-Step Guide