Learn the Basics of Selecting an Appropriate Temperature Controller For Your Application

Discover key considerations, sensor compatibility issues and industry requirements when choosing a temperature controller suited for your specific use with this comprehensive guide. Make an informed choice!

1. Introduction

Temperature control is an integral component of many industries, ensuring optimal conditions for processes and products. Temperature controllers play an essential part in this by regulating heating and cooling systems - and this article offers a detailed guide for selecting an apt one based on industry requirements and key considerations.

2. Understanding Temperature Controllers

A temperature controller is an electronic device used to maintain an ideal environment at specific temperature settings by constantly measuring current conditions, comparing to an established setpoint and making necessary changes to heating or cooling elements to maintain desired temperatures within their specified limits - thus contributing to process efficiency and product quality.

Temperature Controller Types:

There are three basic categories of temperature controllers. These are:

On/Off Controllers:

These controllers work by switching their output on and off when temperature exceeds a pre-set threshold, making them simple yet cost-effective; however, their use could result in temperature oscillations.

Proportional Controllers:These controllers adjust output in proportion to any difference between setpoint and measured temperature, providing more stable control than on/off controllers.

PID Controllers:

Proportional-Integral-Derivative (PID) controllers utilize proportional controls along with integral and derivative adjustments to eliminate steady state error while improving response time, making these controllers ideal for applications requiring precise temperature regulation.

3. Key Considerations

When purchasing a temperature controller, several key aspects must be kept in mind to ensure optimal performance and reliability:

Accuracy and Precision:

Accuracy and precision are critical in maintaining consistent temperatures that ensure product quality and process efficiency, so search for controllers with low tolerance levels and high resolution sensors to achieve this task.

Response Time of Temperature Controllers:

Response time refers to how quickly temperature controllers respond to changes. Quick responses times are essential in dynamic processes where fluctuations could potentially have detrimental consequences on product quality.

Durability and Reliability:

Industrial environments can be harsh environments, with chemicals, moisture, and mechanical stress all present. Choose controllers which are robust yet dependable enough to withstand these challenging environments for best results in your application.

Ease of Use:

User-friendly interfaces and integration capabilities make managing temperature control systems simpler for operators. Look for controllers featuring intuitive displays, remote monitoring capabilities and compatibility with existing control systems for optimal temperature regulation.

Cost-Effective Operations:

Striking the optimal balance between performance and budget considerations is vital to running cost-effective operations. Although high precision controllers may carry higher upfront costs, their long-term benefits include decreased errors and enhanced process efficiencies which translate to significant cost savings over time.

Advanced Features:

Today's controllers boast advanced features like programmability, connectivity and data logging which enhance their versatility and increase functionality for improved process optimization and greater control. Taking advantage of such advanced capabilities can bring many insights for process optimisation and improvement.

4. Sensor Compatibility

Temperature controllers rely on sensors to measure current temperature. Popular types include thermocouples, Resistance Temperature Detectors (RTDs), and thermistors; thermocouples can measure wide temperatures efficiently while cost-effective RTDs offer precision applications while quick responding thermistors offer quick responses within certain temperature ranges.

Align Sensors with Controllers: Proper pairing between sensors and controllers is critical to accurate temperature measurements. As different sensors produce differing types of signals (voltage or resistance), selecting a controller capable of processing those particular types is also key to accurate temperature readings.

5. Application-Specific Requirements

Each industry has unique temperature-control needs that must be fulfilled for proper operations, here are a few examples to illustrate them:

Industry Processes: Temperature control in manufacturing and chemical processing is integral to product quality and safety. Temperature controllers ensure processes such as curing, drying and chemical reactions take place at their ideal temperatures for optimal outcomes.

HVAC Systems: Heating, ventilating and air conditioning (HVAC) systems rely heavily on temperature controllers to create comfortable indoor environments that meet safety requirements. Controllers control heaters, air conditioners and fans to achieve desired temperatures for indoor comfort.

Laboratory Equipment: Scientific research and experiments require precise temperature regulation for successful results. Temperature controllers can help create stable conditions during experiments within laboratory ovens, incubators and environmental chambers to keep temperature steady during research sessions and experiments.

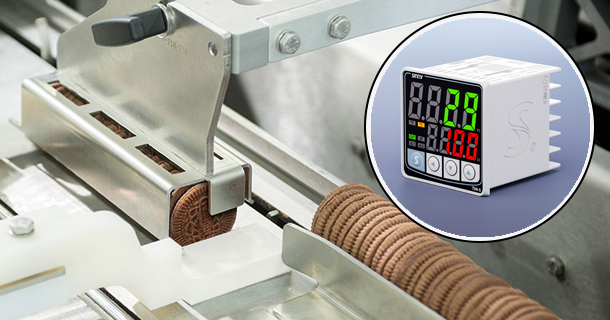

Temperature Control in Food and Beverage Production: To ensure product quality and safety, temperature controllers play an essential role in this industry. Temperature controllers maintain proper conditions during processes like cooking, pasteurization, fermentation and storage processes.

Pharmaceuticals: Temperature controllers play an integral part in pharmaceutical production and storage. By ensuring manufacturing takes place at appropriate temperatures, temperature controllers ensure product efficacy and safety are upheld during the entire manufacturing process.

6. Benefits of Using the Right Temperature Controller

Employing the Appropriate Temperature Controller Implementing the appropriate temperature controller has many advantages:

Improved Product Quality:

Consistent temperature regulation ensures superior product outcomes, minimizing defects while raising quality overall.

Increased Efficiency:

Advanced features like programmability and connectivity help minimize downtime while increasing productivity for more cost-efficient operations.

Energy Savings:

Efficient temperature control can dramatically cut energy use, cutting operational costs while contributing towards sustainability initiatives.

Accurate Temperature Control Aids in Satisfying Industry Standards and Requirements, Preventing Penalties: Maintaining accurate temperature controls helps comply with industry standards and regulatory requirements, helping meet compliance while avoiding penalties.

Modern controllers feature data logging and connectivity features for enhanced data management and better process control, providing crucial insights needed to optimize processes and enhance control capabilities.

7. Consulting Experts

Understanding Expert Advice:

Engaging with industry experts or manufacturers for advice tailored specifically to your individual needs can provide invaluable insights and recommendations tailored to meeting these requirements. They are adept at helping navigate through the complexity of temperature controller selection process to find you an appropriate option that is customized just for you.

Best Practices for Selecting and Implementing Temperature Controllers:

Follow best practices when it comes to choosing and installing temperature controllers, including conducting extensive research, considering multiple options, and testing controllers under real conditions before finalizing your selection criteria. Continually update it based on new technological innovations or changes to process requirements so as not to fall behind on keeping pace.

8. Conclusion

Selecting an optimal temperature controller is integral for maintaining optimal conditions in various industrial applications. By understanding different types of controllers available and relevant industry-specific requirements, making an informed choice can help improve product quality while increasing productivity while assuring regulatory compliance.

- Selecting Sensors for an Industrial Temperature Controller: A Comprehensive Overview

- Industrial Temperature Controllers: Key Features and Applications