PID Temperature Controller SSR: A Comprehensive Guide

1. This article will explore the integration of SSR with PID controllers, types of temperature controllers, what to look for when selecting one and applications.

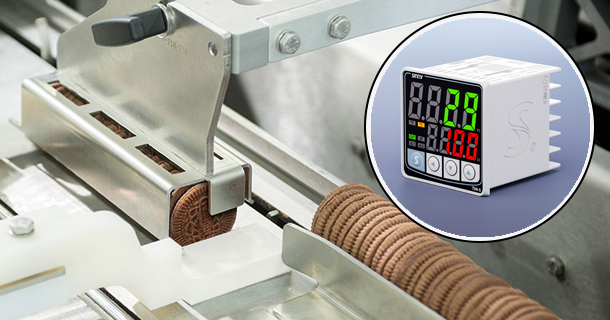

2. SSR and PID temperature controllers work together

The proportional component responds to current errors. Integral accounts for previous errors. And the derivative component predicts errors in the future. They work together to ensure stable and accurate temperature control.

The solid state relay has no moving components, so it operates quietly and reliably. They can also handle large currents and switch quickly without creating sparks or noise. With PID controllers SSRs improve performance through precise, rapid switching. This results in more accurate temperatures.

3. Different types of temperature controllers that use SSR and PID

Analog vs. Digital Controllers There are analog and digital PID controllers. Digital controllers have advanced features like programmable setting, digital display, and communication interfaces. Analog controllers are less complex and cheaper, but they are also more precise and flexible. Analog controllers can be used for simple temperature control, but digital controllers work best for high-precision applications.

Multi-Loop Vs. Single-Loop Controls PID single-loop controllers control one process variable (such as temperature) at a specific locati0n. Multi-loop PID controllers, on the other hand, can control multiple variables at once. In complex applications, where several parameters must be coordinated in real time, multi-loop control is beneficial. These controllers are more efficient and can reduce the number of individual controllers.

4. What to consider when choosing a PID temperature controller with SSR

Requirements You must match SSR specs with your load requirements. SSRs must be able to handle voltage and current requirements for the load. An SSR that is overloaded can cause it to heat up and fail.

Accuracy of Control and Precision PID controllers must be accurate and precise to achieve the temperature desired. To ensure accurate and consistent temperature regulation, look for controllers that have high-resolution sensor and advanced control algorithms.

Environment Take into consideration the environment in which the SSR and PID controller operate. The controller's performance can be affected by factors such as humidity and ambient temperature. Select a controller designed to handle the conditions in your specific application.

Other Features The PID controller can be enhanced with advanced features like auto-tuning and programmable outputs. The auto-tuning feature simplifies setup by adjusting PID parameters automatically. Programmable outputs enable flexible configurations. Integration with industrial control systems is possible through communication interfaces.

5. Popular Models and Brands

The innovative PID controllers from Eurotherm with SSR are suitable for many applications. The controllers range in price from $200 to $2,500 and offer advanced functionality and high precision.

6. Installing and Setting Up

Configuration After installing the controller, configure it according to your needs. The desired temperature, the PID parameters and other features are set. The calibration ensures the controller measures temperature accurately and regulates it. For optimal performance, it is recommended that you perform regular calibration checks.

Safety Issues When working with electrical equipment, safety is of paramount importance. The controller's performance and safety can be affected by moisture or dust. Follow all manufacturer safety instructions and use proper grounding.

7. Application of PID temperature controllers with SSR

Hobby and DIY Projects Hobbyists, DIY enthusiasts and PID temperature controls with SSR can all benefit. They can also be used for projects like home brewing and aquariums.

- What PID Controllers Do When used for temperature control

- PID temperature controller prices: factors, ranges and tips