Selecting Sensors for an Industrial Temperature Controller: A Comprehensive Overview

Discover how to select suitable sensors for an industrial temperature controller by consulting this comprehensive guide. Explore various sensor types, key considerations and application-specific needs while following expert suggestions.

1. Accuracy with Sensor Types

Accurate temperature reading requires selecting an ideal sensor type for your industrial temperature controller; each offering their own benefits and drawbacks. With so many available today with varying specifications and functions available to choose from, selecting an apt one could save your company costly misreadings!

Thermocouples:

Thermocouples have become widely utilized due to their wide temperature range and durability; consisting of two metal wires joined at one end that produce voltage that fluctuates according to temperature changes, thermocouples can cost-effectively measure extreme temperatures but may lack accuracy compared to more accurate sensors.

Resistance Temperature Detectors (RTDs):

RTDs provide precise temperature sensing across an extensive temperature range by sensing changes to metal resistance as a temperature fluctuates; typically platinum resistance changes with temperature shift, offering precise monitoring capabilities unrivaled by thermocouples and thermometers.RTDs may cost more, but their greater precision and repeatability more than make up for any additional expenditure they might require.

Thermistors:

Thermistors are temperature-sensitive resistors which display an abrupt change in resistance as temperature fluctuates, providing precise and responsive temperature regulation compared with thermocouples or RTDs; however, their temperature ranges can be limited making them ideal for applications needing precise temperature regulation within specific ranges.

Infrared Sensors:

Infrared sensors measure temperature by detecting infrared radiation that objects emit and using that radiation as an indirect form of measurement to calculate temperatures. Since infrareds don't rely on physical contact to make measurements, infrareds make ideal tools for tracking moving or inaccessible object temperatures without risk of interruption by physical contact interruption or interference; they may still be affected by environmental factors like dust or humidity however.

2. Key Factors to Consider

Before purchasing industrial temperature controller sensors, several key points should be kept in mind to ensure optimal performance and dependability of these instruments.Accuracy: Accuracy should always take precedence in applications where precise temperature regulation is key; tolerance often plays an integral part of this equation. Make sure the sensor meets any required accuracy specifications of your process.

Response Time of Sensor:

Sensor response times measure how quickly they detect and respond to temperature fluctuations; for dynamic processes that fluctuate quickly in temperature levels, fast responses times are essential requirements.

Temperature Range:

Different sensors feature various operating temperature ranges; to select one that accurately measures temperatures within your parameters for measurement is essential.

Durability and Environmental Conditions:

Industrial environments can be harsh environments for sensors used in applications, with chemical exposure, moisture intrusion and mechanical stress all potentially challenging their operation. When choosing sensors suitable to your environmental specifications it's essential they can stand the tests without fail.

Budget Considerations:

As with any purchase decision comes the need for budget considerations as well as potential long-term cost savings from investing in high precision sensors that reduce errors while improving process efficiencies.

3. Think About Application Requirements

Each industrial application demands specific temperature sensor specifications when making purchases for this application, so when choosing temperature sensors it is vitally important that all necessary details regarding these needs be considered when choosing them for purchase.

Establish Your Process Requirements:

Consider which sensors best fulfill the unique demands of your process, such as high temperature furnaces. A thermocouple could offer greater temperature regulation; but for laboratory environments requiring precise controls an RTD might prove better-suited.

Installation Restrictions:

When choosing and installing sensors, be mindful of available physical space constraints as certain models require larger areas or particular mounting solutions for optimal operation and upkeep. Give priority to devices which meet both installation and upkeep needs within this constraint.

Maintenance and Calibration:

For long-term sensor accuracy, regular calibration and maintenance must take place regularly to keep accuracy intact. When choosing an easy sensor model with less downtime/operational expenses it can make this easier than ever!

4. Compatibility With Temperature Controllers

It is of utmost importance that sensors and temperature controllers work harmoniously together for accurate temperature measurements that integrate easily into daily life.

Signal Compatibility:

Different sensors generate various forms of output signals such as voltage or resistance; therefore it's imperative that their output signal matches up perfectly with what your temperature controller requires.

Integration:

When considering which sensor will best integrate into your current system, take note of any additional signal conditioning or interface modules it might require and try selecting one without extensive modification to existing infrastructure.

5. Case Studies and Examples

Real-life examples and case studies can offer valuable insight into how temperature sensors have been implemented successfully across industries.

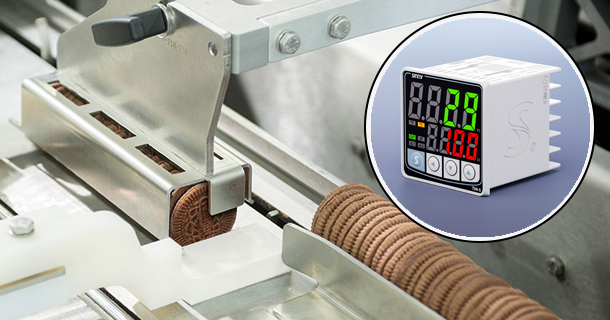

Food & Beverage Industries Employing RTDs due to their accurate temperature regulation during processing; on the other hand, steel mills often utilize thermocouples due to their ability to measure extreme high temperatures accurately.

Success Stories:

One pharmaceutical manufacturer successfully implemented thermistors into their production line to accurately control temperatures for optimal product quality and decreased waste production, while an automotive manufacturer used infrared sensors on their assembly line to track moving parts' temperatures to increase process efficiency and ensure worker safety.

6. Expert Recommendations

Consultation of experts and implementation of best practices can greatly simplify the selection process of an ideal temperature sensor.

Consult With Industry Professionals or Sensor Manufacturers:

Seeking advice from industry professionals or sensor manufacturers can bring invaluable insight. Experts can facilitate an efficient selection process so that the perfect sensor option can be chosen.

Best Practices for Sensor Selection: For successful sensor selection, follow best practices such as conducting extensive research, considering all available options and testing them under real world conditions prior to making a selection decision. Regularly revisit and revise your selection criteria so as to stay abreast of technological advancements as well as changes in process needs.

- Temperature Controller Buying Guide: Things To Consider

- Learn the Basics of Selecting an Appropriate Temperature Controller For Your Application