Temperature PID Controllers: Ensuring Precision in Process Control

Welcome to the world of industrial precision with our comprehensive guide on temperature PID controllers! Get familiar with their components, functions and their essential role in maintaining process stability across various industries.

1. Introduction

Precision in industrial control systems is of utmost importance. One component essential to maintaining this precision is a temperature PID controller - Proportional, Integral and Derivative controllers play an essential part in creating stable processes involving temperature. In this article we investigate their workings as well as components used to form such PID controllers and explore its significance across several industries.

Understanding the PID Components

The PID controller is an elegant solution to process control, utilizing three distinct actions to maintain control over temperature fluctuations.

2. Proportional Control (P)

The proportional aspect of the controller deals with the present state of the error, which is the difference between the desired setpoint and the current temperature. The controller responds proportionally to this error, meaning the corrective action is directly related to the size of the error. The formula for the proportional control can be expressed as:

$$ P_{out} = K_p \times e(t) $$

where ( P_{out} ) is the proportional output, ( K_p ) is the proportional gain, and ( e(t) ) is the current error.

3. Integral Control (I)

Integral control takes into account the accumulation of past errors. If there's a persistent, steady-state error, the integral component works to eliminate it by integrating the error over time. The mathematical representation is:

$$ I_{out} = K_i \int e(t) dt $$

where ( I_{out} ) is the integral output, ( K_i ) is the integral gain, and the integral of ( e(t) ) represents the sum of past errors.

4. Derivative Control (D)

The derivative component predicts future errors by considering the rate at which the error is changing. It helps to dampen the system response and prevent overshooting the setpoint. The derivative control is given by:

$$ D_{out} = K_d \frac{de(t)}{dt} $$

where ( D_{out} ) is the derivative output, ( K_d ) is the derivative gain, and ( \frac{de(t)}{dt} ) is the rate of change of the error.

Sensor Feedback and Setpoint

At the heart of the PID controller's functionality is the feedback from temperature sensors, such as thermocouples or RTDs (Resistance Temperature Detectors). These sensors provide real-time data on the process temperature, which the PID controller compares against the setpoint—the target temperature to be maintained.

PID Controller Algorithm

A PID controller uses an intricate algorithm which takes sensor feedback, calculates error, applies PID formula corrections as appropriate and then alters power supplied to heating or cooling elements as appropriate to achieve as close an accuracy to setpoint temperature as possible. Its output then controls this power in turn ensuring temperature remains as close to desired setpoint value.

Output Adjustment and System Response

A PID controller produces an output signal which modulates energy supplied to processes - for heating elements this could involve altering their electrical current while for cooling systems this might include altering refrigerant flow rates. As fluctuations occur within temperatures, its outputs adjust continuously in response to keep processes stable.

Tuning the PID Controller

Tuning a PID controller requires setting its values of K_p, K_i and K_d to suit the dynamics of each specific process, while simultaneously making sure it responds quickly without creating instability or oscillations.

PID Controller Applications

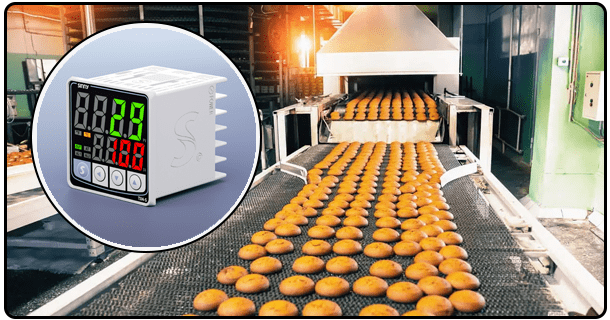

Chemical processers rely on PID controllers to ensure reactions occur at optimal temperatures while food manufacturers rely on them for cooking or refrigerating operations. Environmental control systems in buildings likewise utilize these controllers in order to keep living spaces comfortable for residents as well as employees alike.

Temperature PID controllers have become an indispensable asset in modern industry, helping businesses increase efficiency, product quality and safety while keeping costs under control. Technology continues to advance while PID controllers become ever more precise and reliable at controlling processes.

Related product links

- Temperature Regulation at its Finest: Benefits of PID Temperature Controllers

- Mastering Precision: Advanced PID Temperature Control Systems