Top 10 Industrial Applications of Temperature Controllers

Here are the top 10 industrial applications of temperature controllers, from plastic molding and food processing to pharmaceuticals. Find out how precise temperature regulation enhances efficiency, safety and product quality across various industries.

Temperature controllers serve many industrial uses

1. Plastic Injection Molding

Those in the plastic injection molding industry require temperature controllers to precisely manage melting and molding plastic materials into quality, defect-free products that provide high returns on investments. Poor temperature management could result in warping, shrinkage or poor surface finishes from molds resulting in costly delays for production lines or poor product quality overall resulting in late deliveries or late product quality overall.

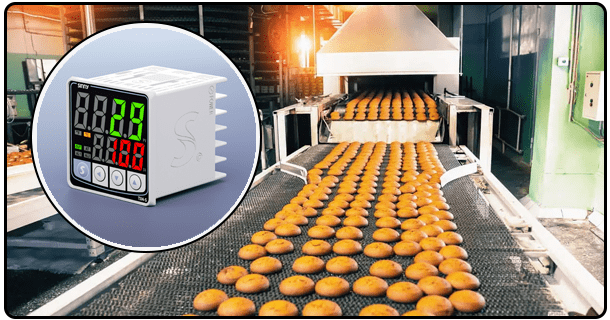

2. Food and Beverage Processing

Temperature regulation is of great significance in food and beverage processing industries such as pasteurization, fermentation and refrigeration processes. Precise temperature management during pasteurization ensures effective microorganism killing without diminishing nutritional values and taste; optimal temperature settings during fermentation ensure consistent product quality when making beer or yogurt for instance.

3. Pharmaceutical Manufacturing

Temperature management is key in pharmaceutical production to ensuring drug efficacy and stability, from synthesizing, crystallization and storage needs through to vaccination needs - any deviations could compromise product quality and safety.

4. Chemical Processing

Chemical processing industries rely heavily on temperature controllers to regulate chemical reactions, ensure reaction rates remain within acceptable parameters and product yields are within their target goals. Temperature management also increases safety by avoiding runaway reactions which could otherwise produce unexpected outcomes for final chemicals products.

5. Heating Ventilating and Air ConditioningCommercial and industrial buildings employ HVAC (Heating Ventilating and Air Conditioning) systems equipped with temperature controllers to create comfortable indoor environments while simultaneously increasing energy efficiency. By carefully controlling heating and cooling processes, they ensure optimal temperatures and humidity levels are reached, offering optimal occupant comfort while simultaneously protecting temperature-sensitive equipment from potential harm.

6. Metal Heat Treatment

Temperature controllers play an essential role in metal heat treatments like annealing, tempering and quenching processes to achieve desirable material properties in metals undergoing these processes such as hardness hardness flexibility strength levels; improper regulation could result in uneven treatments leading to defects or decreased performance from components undergoing these processes.

7. Semiconductor Manufacturing

The semiconductor manufacturing industry demands precise temperature regulation during processes like wafer fabrication, doping and etching. Temperature controllers play an essential role in assuring uniformity and reliability among semiconductor devices; any fluctuations may lead to defects that compromise electronic component performance leading to expensive recalls.

8. Textile Production

Temperature controllers play a pivotal role in textile production. From dyeing and drying processes through finishing processes such as quilting and finishing, accurate temperature regulation ensures consistent color quality and fabric properties throughout production processes. Dye penetration must also be carefully managed during dyeing so as to produce uniform hue and quality across fabric surface areas resulting in uniform coloring across production stages.

9. Glass Manufacturing

Temperature controllers play a central role in glass manufacturing processes such as melting, forming, and annealing. Maintaining accurate temperatures across products ensures uniform strength; fluctuations could potentially result in defects such as bubbles, striations lines or stress fractures that compromise quality and safety.

10. Automotive Industry

Temperature controllers play an essential part in automotive testing, climate control systems and manufacturing. Engine testing utilizes precise temperature control systems to simulate different operating conditions to test reliability and performance; using temperature controllers during manufacturing helps increase quality assurance as well as ensure component safety and longevity.

Temperature controllers play an essential part in many industrial processes, providing precision to achieve ideal process conditions and product quality, efficiency, and safety. From plastic injection molding to automotive production, temperature controllers offer precision necessary for optimizing product quality, efficiency, and safety - not to mention keeping temperatures even across different processes for modern industry operations.

- Thermostat vs Temperature Controller: Key Differences Explained

- How PID Temperature Controller Work?