Top Industries Benefiting from PID Temperature Controllers

Delve into the critical role of PID temperature controllers in enhancing industrial processes across manufacturing, food and beverage, chemical, pharmaceutical, aerospace, and energy sectors. Discover how these controllers contribute to quality, efficiency, and environmental sustainability.

1. Introduction

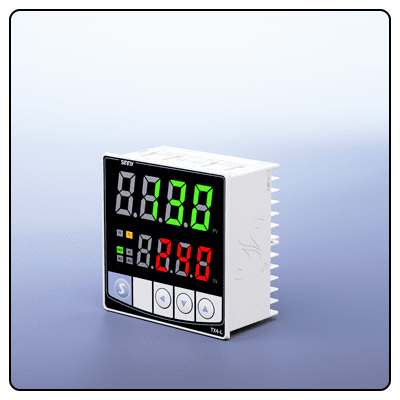

PID temperature controllers are pivotal in industrial automation, offering unparalleled precision in maintaining specific temperatures. Their integration into various sectors has revolutionized processes, ensuring quality, efficiency, and safety.

2. Manufacturing Industry

In the manufacturing industry, PID controllers are indispensable. They ensure that products are crafted under optimal conditions, which is crucial for maintaining quality standards.

• Process Control:

PID controllers regulate temperatures in processes like metal forging and glass production, where specific thermal conditions are essential.

• Quality Assurance:

By maintaining consistent temperatures, PID controllers help in producing uniform and high-quality products.

3. Food and Beverage Industry

The food and beverage industry thrives on consistency and safety, where PID temperature controllers are essential.

• Cooking and Pasteurization:

Precise temperature control is vital for achieving the perfect culinary results and ensuring the safety of food through pasteurization.

• Refrigeration:

PID controllers manage the temperatures in refrigeration units, crucial for preserving food quality and preventing spoilage.

4. Chemical Industry

In the realm of chemistry, reactions are highly sensitive to temperature changes, making PID controllers critical.

• Safety and Consistency:

By maintaining exact temperatures, PID controllers prevent hazardous conditions and ensure consistent product quality.

• Process Efficiency:

Accurate temperature control leads to efficient chemical processes, reducing energy consumption and waste.

5. Pharmaceutical Industry

The pharmaceutical industry demands the utmost precision in temperature control, and PID controllers are at the forefront of meeting this need.

• Drug Formulation:

Precise temperature control is crucial during the drug formulation process to ensure efficacy and stability.

• Storage:

PID controllers are used to maintain specific temperatures for the storage of medications, adhering to strict regulatory standards.

6. Aerospace and Aviation

Temperature control is equally critical in aerospace and aviation, where PID controllers play a key role.

• Environmental Control Systems:

These systems rely on PID controllers to maintain cabin pressure and temperature for passenger comfort and safety.

• Component Safety:

PID controllers ensure that aerospace components operate within safe temperature ranges, preventing malfunctions and ensuring reliability.

7. Energy Sector

In the energy sector, PID temperature controllers are vital for maintaining operational efficiency and safety.

• Power Generation:

PID controllers are used in power plants to regulate the temperature of steam turbines, ensuring optimal performance and preventing overheating.

• Renewable Energy:

With the rise of renewable energy sources, PID controllers are increasingly used to stabilize temperatures in solar panels and wind turbines, maximizing energy output.

8. Plastics Industry

The plastics industry heavily relies on precise temperature control during the manufacturing process to ensure product quality and consistency.

• Molding and Extrusion:

PID controllers are crucial in processes like injection molding and extrusion, where they maintain the correct melting temperatures for various plastics.

• Environmental Impact:

The industry is also exploring the use of PID controllers to reduce energy consumption and minimize the carbon footprint of plastic production.

10. Conclusion

PID temperature controllers have become an integral part of modern industry, playing a critical role in a wide range of applications. Their ability to maintain precise temperature control has led to improvements in product quality, process efficiency, and environmental safety. As industries continue to evolve and new challenges arise, PID controllers will remain essential tools in the quest for innovation and sustainability.

- Troubleshooting PID Controllers: Expert Solutions to Address Common Concerns

- Maximizing Output with PID Temperature Controllers