Troubleshooting PID Controllers: Expert Solutions to Address Common Concerns

Learn expert strategies for diagnosing and solving PID temperature controller issues with our comprehensive guide. With practical troubleshooting tips that ensure peak performance for industrial systems.

1. Introduction

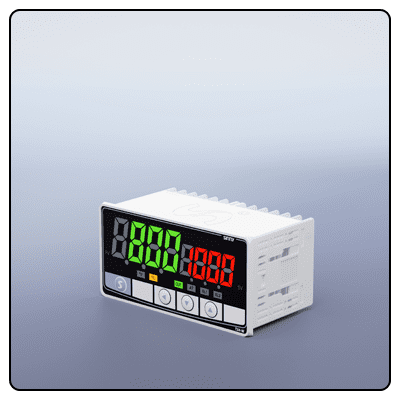

PID temperature controllers are essential players in industrial automation's intricate dance, orchestrating processes at exactly the right tempo while remaining silently reliable. But even these robust systems may occasionally encounter issues.

2. Preliminary Checks

Before diving deeper into complex diagnostics, start simple. Make sure your power supply is reliable and securely connected to your PID controller; examine all wiring for signs of damage or loose connections; verify temperature sensors are intact and accurate depictions of true process temperatures;

3. Understanding PID Controller Parameters

PID controller parameters are at the core of its performance. Incorrectly configured Proportional, Integral or Derivative values may lead to process instability - become familiar with them so as to understand their influence over controller behavior; symptoms like constant temperature overshoot or delayed responses often point towards incorrect parameter configuration.

4. Diagnostic Steps

When troubleshooting PID controller issues, take an analytical approach. Consult the manual for any specific error codes before using its interface to navigate its diagnostic features - remembering feedback provided by the controller can often reveal where its source lies.

5. Common Problems and Solutions

Certain issues tend to crop up more often. A controller that won't power on or respond could have electrical issues; one which doesn't maintain temperature settings could have sensor issues. Deciphering error messages accurately is key; they provide clues as to where there may be issues within your controller.

VI. Advanced Troubleshooting Techniques

Experienced troubleshooters have many advanced troubleshooting techniques at their disposal that can resolve persistent issues with PID parameters, including noise or oscillation issues in processes. By incrementally altering PID values while closely watching for response from systems, adjustments of this kind may eventually bring harmony back into play and produce desired results.

6. Maintenance Tips

Preventative Maintenance Tip Regular calibration ensures accuracy while inspections help ward off potential problems with PID controllers. Create a maintenance schedule tailored specifically for the demands of your system.

7. When to Seek Professional Help

Sometimes the complexity of a problem requires expert input to resolve. If troubleshooting steps fail to address an issue, seek assistance from either your manufacturer or service technician - they should both offer guidance.

Troubleshooting PID temperature controllers is an art that takes patience and precision. By following the steps outlined in this article, you can address common issues while keeping industrial processes flowing seamlessly. Understand your PID controller is crucial to its proper function!

- Why Choose PID Temperature Controllers Over Traditional Ones

- Top Industries Benefiting from PID Temperature Controllers