Modern Temperature Control Systems: Improve Performance & Efficiency

Explore the key features of modern temperature control systems, including advanced sensors and smart control units that offer remote monitoring, energy efficiency and more. Learn how these innovations have enhanced performance, safety and user experiences across various industries.

1. Introduction

Temperature control systems have become an integral component of many industries, helping ensure optimal conditions for processes, products, and environments across industries such as manufacturing or healthcare. Modern temperature control systems have significantly advanced with sophisticated features designed to increase their efficiency, reliability, user-friendliness, and user benefits; in this article, we highlight these top features of modern temperature systems and their advantages and applications.

2. Advanced Sensors

Modern temperature control systems use advanced sensors, including thermocouples, Resistance Temperature Detectors (RTDs) and infrared sensors that offer precise temperature measurements with exceptional accuracy and reliability. These modern temperature sensors also boast great potential in controlling air pollution by mitigating climate change effects on global warming.

Accuracy and Reliability Improvements: Thermocouples have long been preferred over their alternatives due to their wide temperature range and fast response time; RTDs' excellent stability and accuracy make them suitable for applications requiring precise temperature regulation, while infrared sensors measure temperatures from a distance, making them ideal for hazardous or hard-to-access locations.

Applications in Different Industries: Temperature sensors have various applications across industries, such as manufacturing, healthcare, and environmental monitoring, to provide accurate temperature readings and precise temperature measurements.

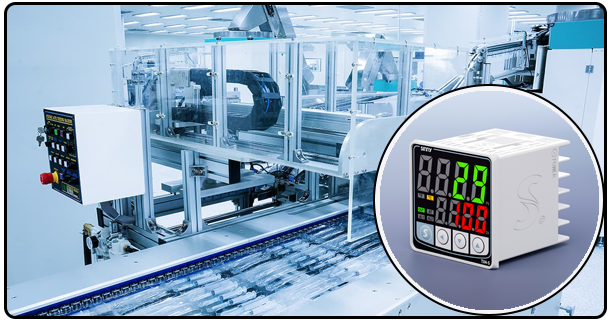

3. Smart Control Units

Integration With IoT and Smart Home Systems: Smart control units have revolutionised temperature regulation systems by harnessing Internet of Things (IoT) connectivity and machine learning algorithms for optimal temperature regulation.

Adaptive Algorithms and Machine Learning Capabilities: IoT-enabled control units can communicate seamlessly with other devices and systems for seamless integration and automation. In contrast, machine learning algorithms enable their control units to adapt quickly to changing circumstances, optimising performance over time.

Benefits for Industrial and Residential Applications: This results in more accurate temperature regulation, cutting energy use and operational expenses in both industrial and residential settings.

4. Remote Monitoring and Control

Mobile App Integration: Modern temperature control systems offer real-time remote monitoring and control functionality, giving users direct real-time access to system settings.

Real-Time Data Access and Alerts: Mobile app integration enables users to monitor and adjust temperature settings from anywhere easily and flexibly, increasing convenience and flexibility. Real-time alerts notify them if issues or deviations from the desired temperature range occur, providing timely corrective and corrective actions as soon as needed.

Use Cases in Healthcare, Manufacturing and More: This feature can be especially advantageous in industries requiring continuous monitoring, such as pharmaceuticals, food storage or manufacturing.

5. Energy-Saving

Modes and Features: Modern temperature control systems include energy-saving modes and features designed to optimise their use without impacting performance, contributing significantly towards energy conservation.

Impact on Operational Costs and Environmental Footprint: For instance, variable speed drives (VSDs) allow compressors and fans to respond more closely to energy demand by adapting their speed based on demand, reducing energy usage, while advanced control algorithms help minimise temperature fluctuations for stable operation and efficient performance.

Examples from Different Industries: By decreasing energy usage, these systems help lower operational costs and contribute towards environmental sustainability in sectors like manufacturing, commercial buildings and residential homes.

6. User-Friendly Interfaces

Touchscreen Displays and Intuitive Controls: Temperature control systems feature user-friendly interfaces in touchscreen displays and intuitive controls that make setting and adjusting temperature parameters simple for end-users.

Customisable Settings and User Profiles: Customizable settings and user profiles allow for c tailored to different applications' requirements.

Enhance Your User Experience in Different Environments: These interfaces often feature visual representations of temperature data to give users a comprehensive picture of system performance. Their ease of use and accessibility enhance user experiences across settings from industrial plants to residential homes.

7. Safety Features

Overheat Protection and Fail-Safes: Temperature control systems play a pivotal role in industries dealing with potentially hazardous materials or processes, so modern systems incorporate numerous safety features like overheat protection and fail-safes for extra precaution. To prevent accidents and ensure the best experience possible for users.

Compliance with Industry Standards and Regulations: Overheat protection mechanisms automatically shut off if system temperature exceeds set levels, protecting users and complying with industry regulations and standards.

Fail-safes ensure the system continues operating safely even in the event of component failure, protecting equipment and products from being compromised by damage caused to them.

Importance in Hazardous Environments: Adherence to industry standards and regulations can further increase system safety and reliability, making them suitable for hazardous environments like chemical plants or laboratories.

8. Integrity Capabilities

Compatibility with Other Systems: Modern temperature control systems require integration capabilities to work seamlessly with other devices and systems, including HVACs, BMSs and industrial control systems. They should also offer advanced features to accommodate new trends like connected refrigeration units.

Scalability for Different Applications: Interoperability allows centralised control and monitoring to increase efficiency and coordination, improving efficiency as a whole. Scalability also plays a vital role, permitting systems to expand or modify in response to changing demands in applications across a broad spectrum.

Benefits for Both Large- and Small-Scale Operations: Integrating temperature control systems with other systems benefits l residential applications, providing added versatility and functionality that benefits them both significantly.

9. Data Logging and Analytic

Modern temperature control systems offer useful capabilities that enable data logging and analytic tracking capabilities for in-depth system evaluation and proactive maintenance, offering insights into system performance as well as creating historical logs with temperature data that can later be examined to detect trends or patterns in behaviour. These features make data tracking both informative and time-saving; modern temperature controllers record temperatures continuously in their historical logs, so analysis of this historical log may reveal unexpected insights or otherwise impossible anomalies.

Predictive Maintenance and Performance Optimization: With advanced analytics tools capable of detecting anomalies and anticipating potential issues before they arise, predictive maintenance enables proactive maintenance that reduces downtime while promoting greater uptime and reduced maintenance costs.

Applications in Research and Development: Leveraging data logging and analytics allows users to optimise system performance, increase efficiency, and prolong equipment lifespan. These capabilities are especially advantageous in research settings that rely heavily on temperature regulation and precise data collection for analysis purposes.

10. Conclusion

Modern temperature control systems have numerous advanced features designed to increase performance, efficiency and user-friendliness. From advanced sensors and smart control units to remote monitoring capabilities and energy-saving features - such as energy-saving capabilities or sensors - modern temperature controllers boast numerous benefits that benefit various industries. Furthermore, safety features, integration features and data logging contribute further reliability and versatility of such devices; with technology continually progressing, we may expect even more innovative features and advancements within these temperature regulation and management tools that advance further advances.

- Top Temperature Control Solutions for Different Applications: An In-depth Guide

- Temperature Control System and Controller: Key Differences