Understanding Digital Temperature Controllers: Types, Applications, and Benefits

Learn about digital temperature controllers, their types, applications, and benefits. Discover how these devices enhance product quality and process efficiency in various industries.

1 . Introduction

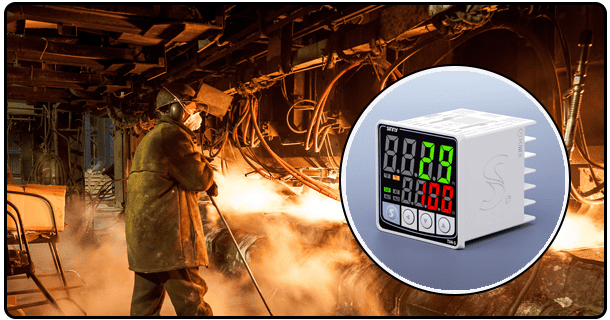

A digital temperature controller is an electronic device used to maintain and adjust desired temperatures by comparing against an established presetpoint and making necessary changes accordingly. They play an essential part in various applications and play an essential part in product quality and process efficiency - crucial components in providing consistent results in industry as well as commercial processes.

2 . How It Works

Digital temperature controllers use temperature sensors like thermocouples or resistance temperature detectors (RTD) to collect current temperatures, sending this information onward to a microprocessor which compares this figure against its setpoint temperature; any discrepancies being corrected through activating heaters, coolers or fans as necessary according to legal compliance.

Starting the process off right, temperature sensors gather data and relay it directly to a controller via microprocessor processing for analysis and decision making based on this information; once made, this controller determines whether temperatures need to increase or decrease accordingly and sends direct output signals directly to output devices to either heat or cool the environment until reaching their target temperatures; ensuring consistent monitoring and adjustment within specified parameters and keeping temperature stable over time.

3 .There Are Different Kinds of Digital Temperature Controllers

Different digital temperature controllers suit specific applications or precision levels.

On/Off Controllers

On/Off controllers are the simplest method of temperature regulation. They work by fully activating or deactivating an output when the temperature rises above or falls below a setpoint. This type of control is ideal for applications where precise temperature regulation is not critical, such as in heating systems.

Proportional Controllers

Proportional controllers offer more refined temperature regulation by producing variable output that narrows the gap between setpoint and actual temperature rather than simply turning fully on or off as with on/off control systems. Furthermore, proportional controls offer precise temperature regulation making them suitable for applications where keeping steady temperatures is paramount.

PID Controllers

Proportional-Integral-Derivative controllers combine proportional, integral and derivative control techniques in order to deliver highly precise temperature regulation. Proportional component is responsible for correcting current errors while integral corrects past ones while derivative anticipates any future ones; with such combination providing tight temperature management in applications demanding precise temperature management.

4 . Applications

Digital temperature controllers find extensive use across a wide variety of industries. Examples of applications for such controllers may include:

Food Processing:

These processes use precise temperatures during baking, cooking and refrigeration processes in order to produce safe food with exceptional taste and aroma.

Consumer Electronics:

They assist in controlling temperatures in devices like ovens, fridges and air conditioners in order to increase performance and extend lifespan.

Temperature controllers play an essential role in industries including manufacturing, automotive, aerospace and medical device production. Proper temperature management ensures product standards and enhanced performance - something temperature controllers help achieve.

5.Benefits

Digital temperature controllers come with many significant advantages:

Improve Product Quality:

Precise temperature controls ensure products are manufactured precisely to their specifications, thus decreasing defects and increasing overall quality.

Improved Process Efficiency:

Digital temperature controllers contribute to greater process efficiencies by maintaining optimal temperatures, helping streamline business activities while decreasing waste while increasing productivity.

Energy Savings:

Efficient temperature regulation can lead to significant energy savings by minimizing the energy necessary to reach and sustain desired temperatures.

Decreased Manual Intervention:

Automated temperature controls allow personnel to make less adjustments manually, freeing them up for other duties.

6. Best Practices

For maximum performance from digital temperature controllers, best practices must be observed during their selection, installation and ongoing management. In order to do this effectively.

Regular Calibration and Maintenance:

For accurate temperature regulation that won't compromise product quality, regular calibration and maintenance on temperature sensors and control units should be carried out to maintain consistent accurate temperatures throughout time. Doing this ensures accurate regulation is in effect at all times.

Proper Selection:

Choose the appropriate type of digital temperature controller based on the specific requirements of the application, including the desired temperature range and level of precision.

System Integration:

Integrate the digital temperature controller with other control systems to achieve seamless operation and monitoring. This can enhance overall process efficiency and quality control.

7 . Conclusion

Digital temperature controllers play an essential role in modern manufacturing and other industries, providing precise temperature regulation across a range of applications. By understanding their operation, types, applications and benefits users can make informed decisions to enhance production capabilities while employing best practices with regards to these controllers can ensure consistent product quality, enhanced process efficiencies and significant energy savings.

- What is a Temperature Controller and How Does It Work?;Comprehensive Guide

- Understanding Mold Temperature Controllers: Types, Applications, and Benefits