What is a Temperature Controller and How Does It Work?;Comprehensive Guide

Discover what a temperature controller is and its workings. Explore different types, components and applications as well as its uses across industries.

1. Introduction

Temperature controllers are devices used to maintain desired temperatures within specified limits. Temperature controls play an integral part in all kinds of processes ranging from industrial operations and consumer products, helping ensure systems run safely. It plays a pivotal role in product quality assurance, energy savings, operational stability and system effectiveness.

2. Types of Temperature Controllers

Temperature Controller Types There are various kinds of temperature controllers designed for various uses and levels of precision, all which have different applications and purposes.

On/Off Controllers:

These controllers offer simple temperature regulation by activating or deactivating output when temperatures cross their setpoint, making it simple and user friendly, but may cause temperature oscillations around that target value - making them unsuitable for applications which demand precise control.

Proportional Controllers:

Proportional controllers reduce oscillation by adjusting output power proportionally with temperature differences between setpoint and current temperatures - creating more stable temperature control compared to On/Off controllers.

Its PID Controllers (Proportional-Integral-Derivative):

PID controllers offer advanced level temperature maintenance technology by combining proportional with integral and derivative actions to correct errors while anticipating temperature shifts, maintaining stable temperatures in an accurate way.

3. Components of a Temperature Control System

A typical temperature control system typically comprises three main elements. These are:

Sensors:

measure current temperatures using thermocouples or Resistance Temperature Detectors (RTDs). They supply data necessary for controllers to make necessary adjustments.

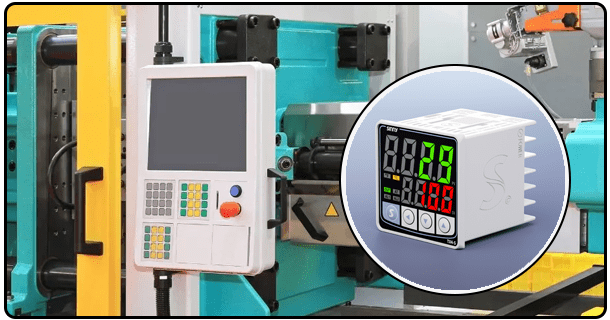

Controllers:

Controllers serve as the nerve center of any temperature management system, processing sensor data to make necessary adjustments that maintain desired temperatures. These controllers may either be digital or analog; digital controllers typically offer more advanced features and programming abilities.

Control Elements:

Heaters or coolers that actually modify temperature settings; their controller sends signals to these elements so as to adjust up or down as required.

4. How Temperature Controllers Work

Temperature Controllers Work The principle behind how temperature controllers function can differ depending on their type; in general though they all work similarly.

On/Off Control:

With this approach, if the temperature deviates from its setpoint it simply switches the control element on or off accordingly - simple but potentially leading to significant temperature swings which makes this method unsuitable for critical applications.

PROPORTIONAL CONTROL:

Proportional controllers use output power adjustments based on any deviation between temperature setpoint and actual. This decreases temperature oscillation amplitude while offering more stable temperature regulation.

PID Controls:

PID controllers combine proportional, integral, and derivative actions in order to achieve precise control. Proportional actions address present errors while integral actions correct past ones while derivative ones anticipate potential future errors - providing reliable temperature regulation with minimum deviation from setpoint values and stable temperature stability.

5. Temperature Controller Applications

Temperature controllers have many uses in various fields and industries, including:

for Scientific Research:

Laboratories and research facilities utilize temperature controllers to maintain specific conditions necessary for conducting their experiments accurately, thus producing reliable results.

6. Utilization of Temperature Controllers

Implementing temperature controllers within various systems offers numerous advantages:

Improved Process Efficiency:

By keeping temperatures within ideal ranges, processes can run more efficiently, decreasing waste while increasing productivity.

Improved Product Quality:

Consistent temperature controls help manufacturers meet high quality manufacturing standards for each batch produced, decreasing defects while improving overall product quality.

Energy Savings:

pid temperature controller digital reduces resources, saves costs and does not impact the environment

7. Conclusion

Temperature controllers have become an integral component of modern technology, providing accurate and dependable temperature management across various applications. Ranging from simple On/Off controllers to sophisticated PID systems, temperature controllers ensure processes run efficiently, products meet quality standards, energy is used efficiently, and processes stay running on schedule.

- What is a PID Temperature Controller? Comprehensive Guide

- Understanding Digital Temperature Controllers: Types, Applications, and Benefits