What Does A Digital Temperature Controller Do?

Uncover the functionalities of digital temperature controllers and how they bring accuracy and efficiency to temperature-dependent processes across industries.

1. Digital Temperature Controllers: The Technological Thermostats

Digital temperature controllers have recently become indispensable process automation tools, serving as technological thermostats with exceptional precision and control of temperature-dependent systems. They are integral in many applications, from industrial manufacturing to household appliances. This article looks into their workings and their role in modern temperature regulation.

2. The Core Components

At the core of every digital temperature controller lie three essential elements.

* Sensors: Instruments like thermocouples or RTDs that measure actual temperatures accurately

* Control Unit: A microprocessor-based system that processes sensor data and makes decisions based on that.

* Output Mechanisms: These elements include relays, fans, or heaters, which can be activated to regulate temperature settings.

3. How They Operate

Temperature controllers work according to an easy principle:

1. Measurement: Sensors gather temperature data and send it directly to the control unit, where microprocessors compare it against the desired target temperature (setpoint ).

2. Comparison: The microprocessor compares actual temperatures against predefined setpoint temperatures set by users or preprogrammed controls in advance.

3. Adjustment: Should an irregularity arise, the controller uses output mechanisms to address it by activating output mechanisms designed to minimize error and achieve setpoint.

4. Diverse Types for Various Applications

Digital temperature controllers come in various varieties to meet specific needs:

* On/Off Temperature Controllers: These provide basic control by switching off or on an output device as desired.

* Proportional Temperature Controllers: Proportional temperature controllers adjust output in response to temperature differences between temperatures.

* PID Temperature Controllers: PID temperature controllers represent a revolutionary solution, using algorithms to anticipate temperature shifts and adapt outputs beforehand.

1. Advantages Over Analog

Digital Temperature Controller Advantages Digital temperature controllers boast various advantages over analog counterparts: * Precision: They allow more precise temperature readings and management.

* Customizability: Users may customize them for specific functions and circumstances.

* Features: These devices often include alarms, data logging capabilities, and communication interfaces for integration into other systems.

1. Where Do Digital Temperature Controllers Shine?

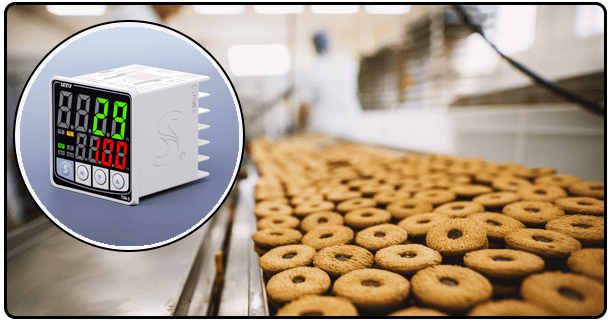

Digital temperature controllers find diverse uses. Digital thermostats are integral in controlling temperatures for HVAC systems, food production lines, and chemical reactors within industrial processes.

Consumer products such as ovens and refrigerators rely on these components to maintain consistent performance and energy efficiency.

Specialized equipment like laboratory incubators provides the conditions necessary for scientific research.

Digital Temperature Controllers have had an immense effect on society over the years.

Here is their impactful tale!

Digital temperature controllers have revolutionized temperature regulation across industries by improving efficiency and quality, streamlining processes, standardizing procedures, and optimizing operations. This has led to enhanced product quality, reduced waste disposal fees, and greater safety measures.