How to Maintain Your Temperature Controller Longevity

Learn the essential practices needed for the longevity of a temperature controller through this comprehensive guide. Regular inspection, calibration, software updates, and environmental considerations are just a few basic maintenance practices outlined.

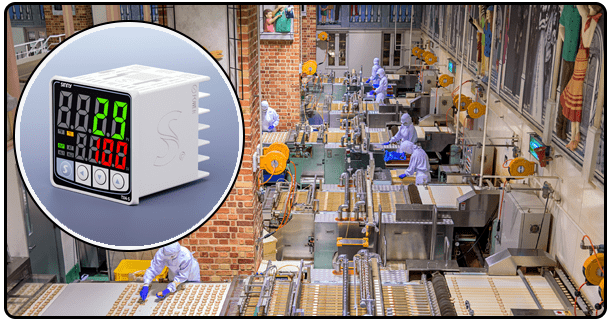

1. Introduction

Temperature controllers play a pivotal role in many industrial and household applications, providing precise temperature management to maximize performance and safety. Proper care must be taken in maintaining these devices to prolong their longevity while upholding accuracy; in this article, we present an in-depth guide for keeping up your temperature controller's longevity by regularly inspecting, calibrating, updating software versions and considering environmental factors.

2. Understanding Temperature Controller Maintenance

Definition:

Temperature controller maintenance entails maintaining its functionality and accuracy over time, helping ensure it functions within its specified parameters while decreasing risks and increasing lifespan.

Temperature Controller Types:

There are different kinds of temperature controllers on the market today, from On/Off and Proportional models to PID controllers, which offer precision. Each has distinct maintenance needs. For example, PID controllers often need more frequent calibration compared to On/Off models.

3. Regular Inspection and Cleaning

Visual Inspection:

A regular visual inspection can be an invaluable way to spot potential issues early on and take immediate steps to rectify them before they worsen. Look for signs of wear, damage, loose connections, and display-based messages or readings that might signal issues on an issue-prone system.

Cleaning:

Maintaining the temperature controller's cleanliness is critical to its proper function, as dust and debris accumulation could result in overheating or electrical problems. A soft, dry cloth should gently dust its exterior and connectors to avoid water or harsh chemicals that could harm its components.

4. Calibration and Testing

Calibration: This step involves making any necessary adjustments to ensure accurate readings are displayed from a temperature controller to maintain accuracy over time. Regular calibration will keep this device accurate - follow these steps if calibrating your temperature controller!

1. Set Up Calibration Tools: Employ a multifunction process calibrator and standard multimeter.

2. Simulate Temperature Inputs: Employ the calibrator to simulate known temperature inputs.

3. Finally, Check The Outcome

Adjust the Controller Settings: You can compare the output from your controller against its simulated inputs and make the necessary changes.

4. Document the Calibration: Please document your calibration results for future reference.

Testing:

Procuring Regular Test Results: Routine tests should be conducted to verify the temperature controller is functioning effectively. Utilize a multimeter to analyze voltage, current, and resistance readings while verifying its response to temperature changes by testing against various setpoint temperatures and responses accurately to changes.

5. Software Upgrades and Firmware Upgrades

Software Updates:

Staying current on software updates for temperature controllers is critical to their optimal functioning, with manufacturers often issuing updates to address bugs, enhance functionality, or strengthen security measures. You can check your manufacturer's website frequently for new releases and follow installation instructions accordingly.

Firmware Upgrades:

Upgrading firmware on controllers can significantly enhance performance and capabilities, such as downloading the most up-to-date version from manufacturer websites to upgrade it and following their instructions as prescribed. Please ensure your device remains connected to an uninterrupted power source during its upgrade to avoid interruptions.

6. Environmental Considerations

Proper Ventilation:

Adequate ventilation is vital in protecting temperature controllers from overheating. Please ensure they're placed in an environment with enough airflow; avoid placing them near heat sources or areas that trap heat.

Temperature and Humidity Control:

Maintaining ideal environmental conditions for temperature controllers is paramount to their long-term functioning. It should always be done in moderation to prevent extreme temperatures or high humidity levels from affecting its performance. Keep the device within an ambient atmosphere with moderated temperatures and humidity levels for best performance.

7. Electrical and Mechanical Maintenance

Secure Connections:

Regularly check and secure all electrical connections to prevent loose or faulty connections, which could result in malfunctions. Also, please review the wiring for signs of wear or damage and replace any worn-out components.

Component Replacement:

Over time, some components of your temperature controller may become worn down or broken and must be promptly identified and replaced for optimal device functioning. Everyday items requiring replacing include sensors, relays, and connectors.

8. Documentation and Record Keeping

Temperature con detailed maintenance logs to document its history. Document all maintenance activities performed, from inspections, calibrations, software updates, and component replacements - noting the date, tools used, and personnel involved for each activity.

Scheduled Maintenance:

Regular upkeep should become part of its routine care by creating and following a maintenance schedule for your temperature controller. Plan and track maintenance activities according to manufacturer recommendations and your application's specific needs - this helps avoid unexpected failures while prolonging its life and lifespan.

Conclusion

Proper maintenance of temperature controllers is vital to their long-term functionality and optimal performance. By adhering to established practices such as inspection, calibration, and software updates, you can maintain their accuracy and reliability - something proper maintenance not only enhances process efficiencies but also promotes compliance with industry standards and enhances compliance.

- Temperature Controller Upgrades: What You Should Know

- How to Calibrate a Temperature Controller for Accuracy