Temperature Controller Upgrades: What You Should Know

Explore the advantages of upgrading your temperature controller. Discover popular upgrades such as PID controllers and Wi-Fi connectivity; get advice for selecting and installing appropriate upgrades; plus learn which upgrades might meet your requirements best.

1. Introduction

Temperature controllers have become integral in various industrial and household applications, providing accurate temperature regulation to optimize performance and ensure safe environments. Upgrading these devices can significantly enhance their functionality, accuracy, and efficiency; this article delves into their benefits, popular upgrade options available, and steps needed for successful implementation.

2. Understanding Temperature Controller Upgrades

Definition:

Upgrading a temperature controller involves upgrading its hardware, software, or firmware to enhance its performance and capabilities. Upgrades may range from simple software updates to more extensive physical changes, each aimed at providing greater control and reliability of operation.

Types of Upgrades:

Available for Temperature Controllers: The following upgrades may be possible on temperature controllers.

* Hardware Upgrades include adding new sensors or components as needed or installing advanced control modules. * Software Upgrades

* Software Upgrades: Updating a controller's software with the most current version may bring new features and enhance existing functionalities, opening up opportunities to expand.

* Firmware Upgrades: Firmware updates can enhance a controller's performance by fixing bugs or adding new capabilities and adding to its overall capability set.

3. Advantages of Upgrading Temperature Controllers

Enhance Accuracy:

Upgrading your temperature controller can significantly enhance its accuracy. Modern controllers feature precise temperature regulation capabilities for applications where minor variances could have significant ramifications; pharmaceutical manufacturing facilities, for instance, depend on maintaining exact temperatures to guarantee product quality and safety.

Enhanced Functionality:

Upgrades may bring with them enhanced functionalities and capabilities such as remote monitoring, data logging, and advanced control algorithms - offering greater flexibility and control to optimize processes more effectively than before - for instance; remote temperature tracking allows users to keep an eye on temperature settings from anywhere around the world ensuring uninterrupted oversight.

Energy Efficiency:

Modern temperature controllers have become more energy-efficient over the years, significantly cutting energy consumption and operating costs while minimizing their environmental footprint. Upgrading to such models could reduce both your bills and environmental footprint significantly - benefiting large-scale industrial applications where significant energy savings may occur.

4. Popular Temperature Controller Upgrades

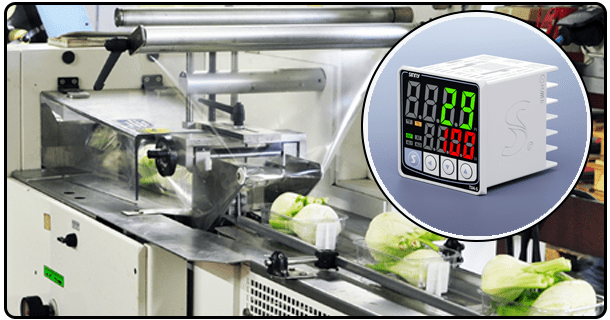

PID Controllers: Proportional-integral-derivative (PID) controllers have quickly become a favorite upgrade choice due to their precision and stability. In contrast to basic on/off controllers, PID controllers constantly adjust output to maintain the desired temperature for more accurate temperature regulation, making these ideal choices for applications demanding precise temperature management.

Wi-Fi Enabled Controllers:

Installing Wi-Fi connectivity into a temperature controller enables remote monitoring and control, making this upgrade especially advantageous in smart home systems and industrial settings that rely on remote access for management purposes. Users with these upgrades can monitor temperature settings remotely using smartphones or computers and receive alerts.

Touchscreen Interfaces:

Upgrading to a touchscreen interface can significantly enhance user experience. Touchscreen controllers are much simpler and more intuitive than their button-based predecessors. They provide transparent and interactive displays that simplify setting and monitoring temperature parameters quickly and precisely - perfect for environments where quick adjustments must occur promptly and precisely.

5. How to Upgrade a Temperature Controller

Assessing Your Needs:

It is vitally important that, before upgrading a temperature controller, an accurate assessment is undertaken regarding personal needs and requirements. You may wish to take into consideration factors like:

* Application Requirements: Determine your exacting accuracy and control needs when considering an application.

* Current Controller Limitations: Please look at its weaknesses and any enhancements you'd like.

* Budget: Prioritise cost when upgrading and ensure it fits within your financial limits.

Selecting an Upgrade:

Determining an upgrade that fits your application and requirements depends heavily upon research; here are a few pointers:

* Investigate: Research various upgrade options carefully regarding their features and benefits before making your choice.

* Seek Advice From Industry Professionals or Manufacturers: For the best upgrades that match your requirements, please ask industry professionals or manufacturers to find an upgrade solution.

* Compatibility: Be sure the upgrade fits your existing system and equipment before purchasing an upgrade.

Installation Process :

The installation process for temperature controller upgrades varies depending on the type of upgrade. Here is a general overview:

* Review Manufacturer Guidelines/Manual: Read through any instructions from your chosen supplier carefully to understand its instructions for proper installation and operation.

* Gather Tools: Before installing anything new or upgrading existing installations, please collect all the necessary tools and equipment needed for successful implementation.

* Take Precautionary Measures: Ensure all safety measures are in place to avoid accidents.

* Install Upgrade: Please follow these step-by-step instructions to install your upgrade.

* Examine Your System: After installation, conduct tests to ensure it satisfies all your specifications and meets your standards.

6. Maintenance and Support for Upgraded Temperature Controllers

Regular Maintenance:

Maintaining upgraded temperature controllers is crucial for their longevity and optimal performance. Regular maintenance includes:

* Cleaning: Keep the controller and its components clean to prevent dust and debris buildup.

* Calibration: Regularly calibrate the controller to ensure accurate readings.

* Inspection: Periodically inspect the controller for signs of wear or damage and replace any faulty components.

Technical Support:

Accessing technical support services is essential when troubleshooting and solving issues related to upgraded controllers, including those from manufacturers. Most manufacturers provide support services, including online resources like manuals, FAQs, and troubleshooting guides as a part of this support service.

* Customer Service: If you need help with technical issues, please contact customer service.

* Warranty: To protect the upgrade investment of your device and yourself from possible failure, always purchase one with an appropriate warranty plan.

7. Conclusion

Upgrading your temperature controller can bring numerous advantages, including improved accuracy, expanded functionality, and greater energy efficiency. By carefully considering your needs, selecting an upgrade, and following proper installation and maintenance protocols, you can ensure your temperature controller works at its peak performance, improving processes and contributing towards overall operational efficiencies and sustainability goals.

- Temperature Controller vs Thermostat: What’s the Difference

- How to Maintain Your Temperature Controller Longevity