PID Temperature Controller with SSR Output: Comprehensive Guide & Applications

Learn about PID temperature controllers with SSR outputs, their configuration, and real-world applications in this comprehensive guide. Achieve precise temperature control and enhance system reliability.

1. Introduction

PID temperature controllers are vital components in precise temperature control systems.

Components of PID Controllers:

·

Proportional (P): Reacts proportionally to the current error.

·

·

Integral (I): Addresses accumulated past errors.

·

·

·

3.

Advantages of SSRs:

·

Longer Lifespan: No mechanical wear and tear.

·

·

Faster Switching: Quick response times.

·

·

Silent Operation: No audible clicking sound.

·

·

High Reliability: Less prone to failures.

·

SSRs are commonly used in temperature control applications where high switching cycles and reliability are paramount.

4. Connecting PID Controller to SSR

Step-by-Step Guide:

Safety Precautions:

·

Always follow the manufacturer's instructions.

·

·

Use appropriate wire gauges and connectors.

·

·

Ensure proper insulation and grounding.

·

5. Configuring PID Controller for SSR Output

Setting Up PID Parameters:

·

Proportional Gain (P): Adjusts the response to the current error.

·

·

Integral Time (I): Adjusts the response to the accumulated error.

·

·

Derivative Time (D): Adjusts the response to the rate of change of error.

·

Tuning the PID Controller:

·

Manual Tuning: Adjust PID parameters based on trial and error.

·

·

Automatic Tuning: Use the auto-tuning feature (if available) to set PID parameters.

·

Common Challenges:

·

Oscillations: Caused by high proportional gain.

·

·

Slow Response: Caused by low integral time.

·

·

Noise Sensitivity: Caused by high derivative time.

·

Troubleshooting Tips:

·

Reduce oscillations by lowering the proportional gain.

·

·

Increase response speed by adjusting the integral time.

·

·

Reduce noise sensitivity by adjusting the derivative time.

·

6. Case Studies and Examples

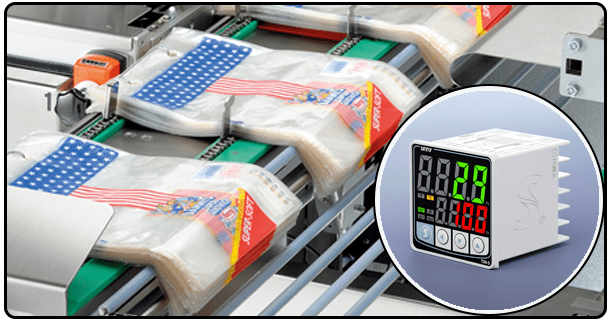

Case Study 1: Manufacturing Industry A manufacturing plant uses PID controllers with SSRs to maintain precise temperatures in their extrusion process. The SSRs provide reliable switching, ensuring consistent product quality.

Case Study 2: Chemical Processing In a chemical processing facility, PID controllers with SSR outputs are used to regulate the temperature of chemical reactors. The precise control provided by the PID controllers ensures optimal reaction conditions, leading to higher yield and product quality.

7. References and Further Reading

·

Using PID Library to control temperature with SSR

·

·

Connecting PID Controller to SSR

·

·

PID Temperature Controller: Everything You Need to Know

·

- Comprehensive Guide to PID Temperature Controller Schematic

- PID Temperature Controller Coffee Machine: Compreh ensive Guide